Page 34 - Folk Boat Year Book 2022

P. 34

Interestingly if you look at the standard GRP Nordic hull viewed from the stern, you’ll

notice that the 10th plank down from the top plank is narrower than the other planks

meaning that the planking on the wooden Nordic which was used as a plug for the

standard GRP version’s hull mould was not quite right. Irritating to the trained eye,

but inconsequential!

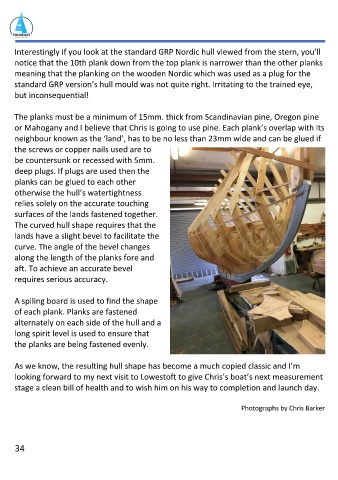

The planks must be a minimum of 15mm. thick from Scandinavian pine, Oregon pine

or Mahogany and I believe that Chris is going to use pine. Each plank’s overlap with its

neighbour known as the ‘land’, has to be no less than 23mm wide and can be glued if

the screws or copper nails used are to

be countersunk or recessed with 5mm.

deep plugs. If plugs are used then the

planks can be glued to each other

otherwise the hull’s watertightness

relies solely on the accurate touching

surfaces of the lands fastened together.

The curved hull shape requires that the

lands have a slight bevel to facilitate the

curve. The angle of the bevel changes

along the length of the planks fore and

aft. To achieve an accurate bevel

requires serious accuracy.

A spiling board is used to find the shape

of each plank. Planks are fastened

alternately on each side of the hull and a

long spirit level is used to ensure that

the planks are being fastened evenly.

As we know, the resulting hull shape has become a much copied classic and I’m

looking forward to my next visit to Lowestoft to give Chris’s boat’s next measurement

stage a clean bill of health and to wish him on his way to completion and launch day.

Photographs by Chris Barker

34