Page 32 - Folk Boat Year Book 2022

P. 32

David Gredley reports on a FB new build

Chris Barker is building a wooden Nordic Folkboat from scratch at the Lowestoft Boat

Building School. Chris’s wife Anne has kindly sent these photographs of the boat in

build. In my capacity as the class’s measurer, I have visited Chris in Lowestoft and

measured the boat in accordance with the first 3 of the 5 stages of measurement

required, compliant with NFIA Rule 1.57. Chris is in the progress of continuing the

boat’s construction for me to complete the 4th stage of measurement which is

planking the hull and fitting the deck beams.

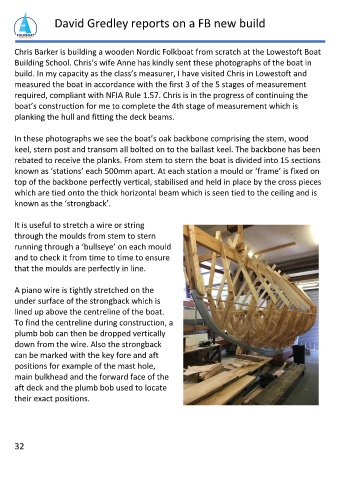

In these photographs we see the boat’s oak backbone comprising the stem, wood

keel, stern post and transom all bolted on to the ballast keel. The backbone has been

rebated to receive the planks. From stem to stern the boat is divided into 15 sections

known as ‘stations’ each 500mm apart. At each station a mould or ‘frame’ is fixed on

top of the backbone perfectly vertical, stabilised and held in place by the cross pieces

which are tied onto the thick horizontal beam which is seen tied to the ceiling and is

known as the ‘strongback’.

It is useful to stretch a wire or string

through the moulds from stem to stern

running through a ‘bullseye’ on each mould

and to check it from time to time to ensure

that the moulds are perfectly in line.

A piano wire is tightly stretched on the

under surface of the strongback which is

lined up above the centreline of the boat.

To find the centreline during construction, a

plumb bob can then be dropped vertically

down from the wire. Also the strongback

can be marked with the key fore and aft

positions for example of the mast hole,

main bulkhead and the forward face of the

aft deck and the plumb bob used to locate

their exact positions.

32